Introduction

The global push toward zero-emission transportation has thrust hydrogen fuel cells into the spotlight, especially for heavy-duty vehicles like trucks, buses, and coaches. Compared to battery-electric solutions, hydrogen fuel cells offer fast refuelling and lighter powertrains, making them an attractive pathway to decarbonise freight and mass transit.

In this post, we’ll cover the basics of how fuel cells work, explore their implementation in heavy vehicles, and explain why they’re a game‑changer for reducing carbon emissions in the transportation sector.

What Is a Hydrogen Fuel Cell?

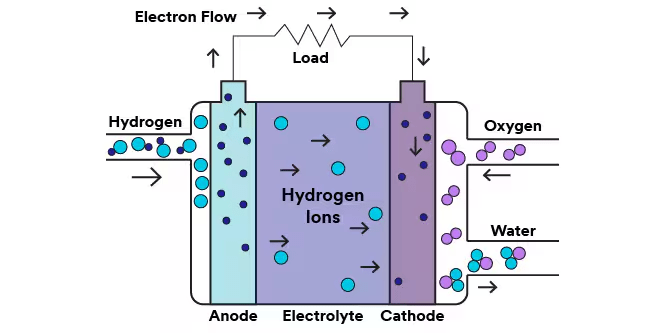

At its core, a hydrogen fuel cell is an energy-conversion device that transforms chemical energy from hydrogen (H₂) and oxygen (O₂) directly into electricity, with water (H₂O) and heat as the only byproducts.

The most common type in vehicles is the Proton Exchange Membrane Fuel Cell (PEMFC).

- Key Components

- Anode (negative side): Hydrogen gas is supplied here and split into protons and electrons

- Electrolyte (membrane): Only protons can pass through to the cathode

- Cathode (positive side): Oxygen (from air) meets the protons and electrons to form water

- Catalysts: Typically platinum-based, speeding up the reactions

- How It Works

- Hydrogen enters the anode and, with the help of a catalyst, splits into protons (H⁺) and electrons (e⁻)

- Protons migrate through the membrane to the cathode

- Electrons travel through an external circuit, generating an electric current to power motors or systems

- At the cathode, protons, electrons, and oxygen combine to produce water vapour and heat

Why Fuel Cells for Heavy Vehicles?

Heavy trucks and buses demand large energy reserves and rapid refuelling—challenges for battery-electric vehicles (BEVs). Fuel cells address these:

- Fast Refuelling: Comparable to diesel—filling up in 10–20 minutes

- High Energy Density: Hydrogen offers more energy per kilogram than batteries, reducing vehicle weight and freeing up payload capacity

- Long Range: Typical heavy‑duty fuel‑cell trucks can cover 400–800 km on a single tank, suitable for intercity routes

- Modular Powertrains: Fuel-cell stacks can be scaled to match power requirements, from yard trucks to 40-tonne + rigs

Real‑World Implementation Examples

| Vehicle Type | MFG/Model | Range | Refuel Time | Status |

|---|---|---|---|---|

| Transit Bus | Toyota Sora | ~200 km | ~10 min | In service in Tokyo, Brussels |

| Coach (Intercity) | Van Hool EX 15H | ~500 km | ~15 min | Demonstration tours in Europe |

Infrastructure and Challenges

- Hydrogen Production:

- Green Hydrogen: Produced via electrolysis powered by renewables—zero emissions, but currently higher cost

- Blue Hydrogen: From natural gas with carbon capture—lower cost but not fully zero‑carbon

- Refuelling Stations:

- A growing network in Europe, North America, and Asia, strategic corridors for freight routes are emerging

- High upfront investment for hydrogen storage, compression, and dispensing equipment

- Cost Considerations:

- Fuel‑cell systems and hydrogen remain more expensive than diesel today

- Total Cost of Ownership (TCO) parity is expected to come by in the late 2020s as technology scales and green hydrogen costs fall

- Durability & Maintenance:

- Fuel‑cell stacks have improved lifetimes (>25,000 hours), but they still require robust thermal and water management

- Technicians need new skill sets for handling high‑pressure hydrogen and fuel‑cell maintenance

Decarbonization Impact

Switching heavy vehicles from diesel to hydrogen fuel cells can dramatically cut CO₂ emissions:

- Zero Tailpipe Emissions: No CO₂, NOₓ, or particulate matter released during operation

- Lifecycle Benefits: With green hydrogen, “well-to-wheel” emissions can be near zero

- Energy System Synergy: Surplus renewable electricity can produce hydrogen via electrolysis, balancing grid fluctuations

- Urban Air Quality: Cleaner fleets in cities reduce smog and health impacts

A fleet of 1,000 fuel‑cell heavy trucks replacing diesel rigs could save upwards of 250,000 Tonnes of CO₂ annually, demonstrating meaningful progress toward net‑zero targets.

What to expect ahead?

As Europe, Asia, and North America roll out hydrogen corridors and as green hydrogen costs fall below $2 per kg, fuel‑cell heavy vehicles are poised for rapid growth. Partnerships between vehicle OEMs, energy companies, and governments will be crucial. Incentives, carbon pricing, and stricter emissions regulations will further accelerate adoption.

Conclusion

Hydrogen fuel cells present a compelling solution for decarbonising heavy trucking and public transport. With fast refuelling, long range, and zero tailpipe emissions, they bridge the gap where batteries alone may fall short.

While challenges in cost, infrastructure, and production remain, ongoing technological advances and supportive policies are paving the road for a cleaner, hydrogen‑powered future in heavy mobility.

Leave a comment